Adhesion

Research background

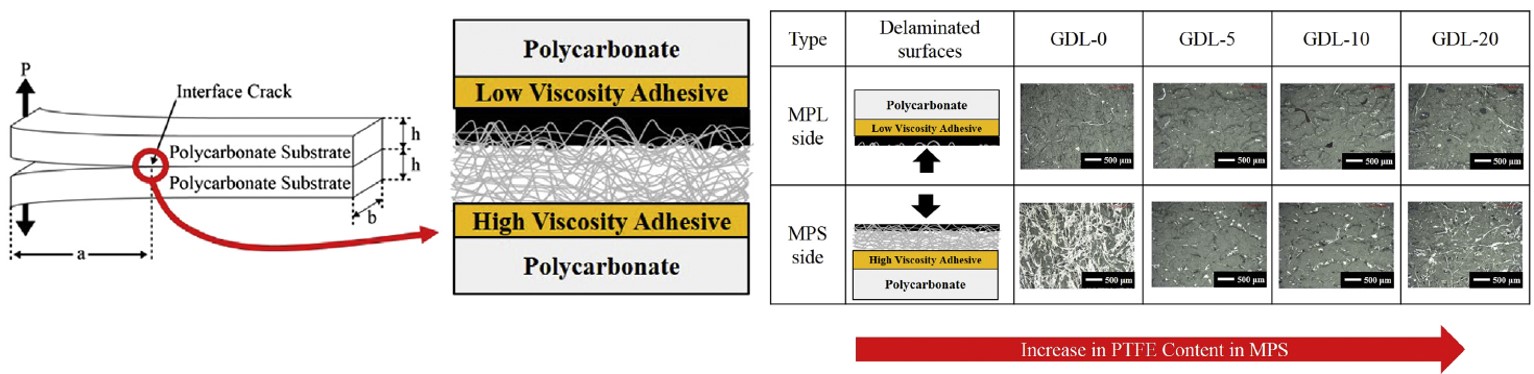

Recently, interfacial reliability is rising for critical issues in various applications such as electronic devices, automobile, fuel cell and solar cell. Therefore, knowing the interfical adhesion energy and delamination mechanism becomes more important for mechanical reliability of designed products.

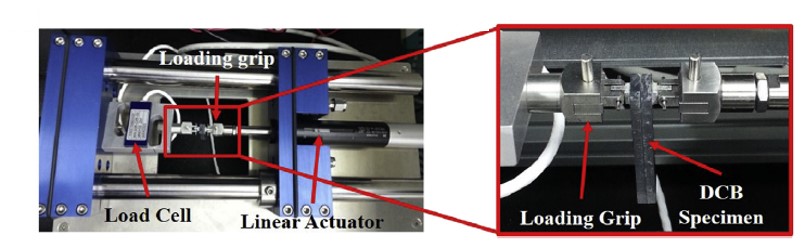

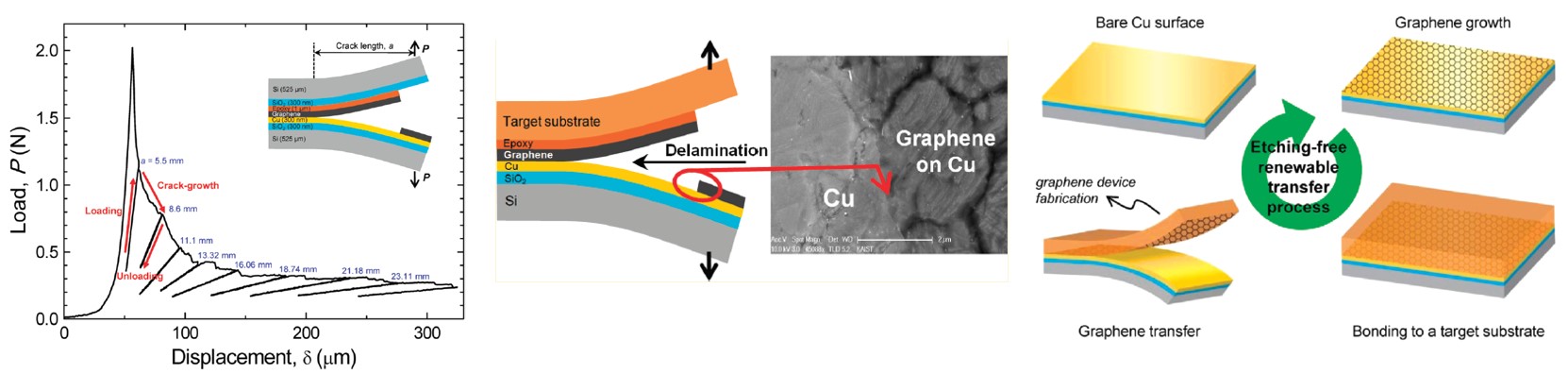

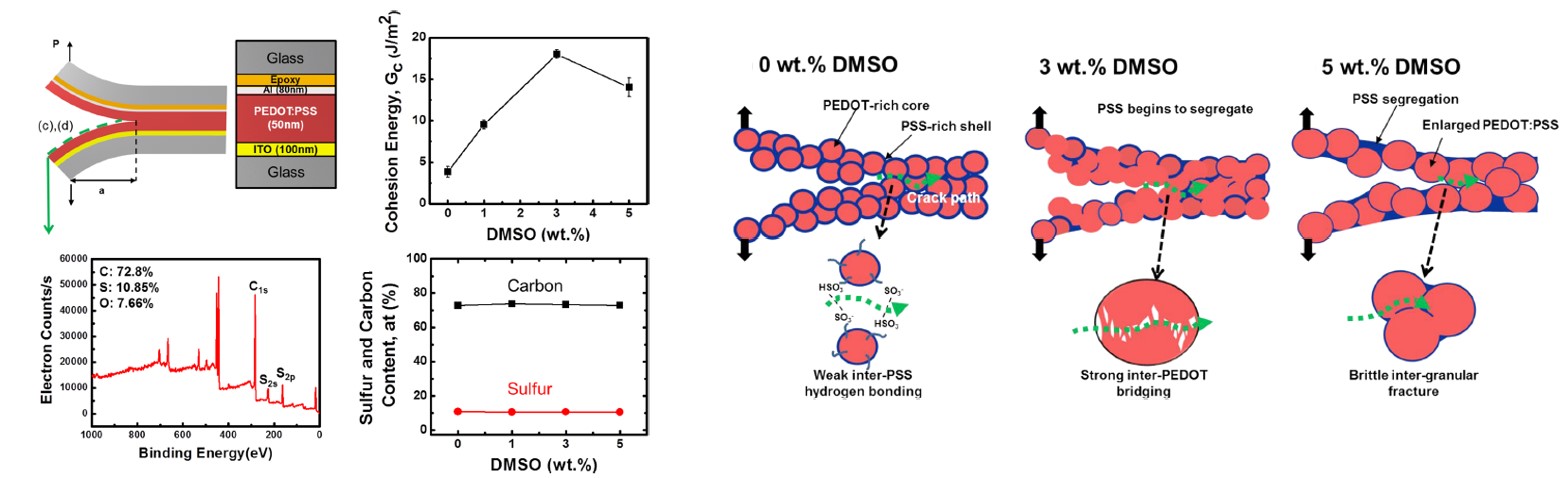

In our research group, the interfical adhesion energy can be quantitatively measured using double cantilever beam (DCB) fracture test.

– Direct measurement of adhesion energy of graphene, and mechanical transfer process

– Adhesion measurement of solar cell and fuel cell

Warpage

Research background

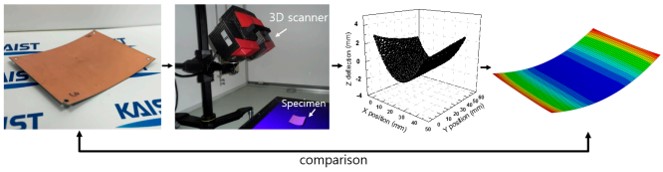

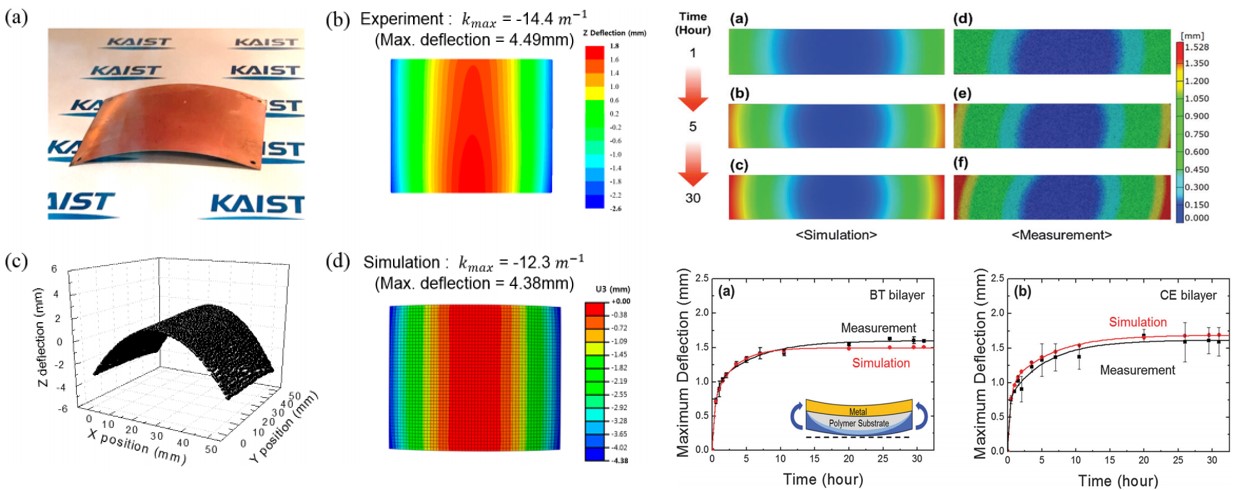

Research on warpage of thin film materials is crucial in terms of mechanical reliability of advanced electronic and energy devices. Systematic study has been performed via theoretical, experimental, and numerical analysis in order to identify various factors of warpage and control of it for future application.

- Development of methodology for warpage analysis

- Analysis and prediction of warpage caused by residual stress and strain mismatch, such as thermal and hygroscopic strain

Fatigue

Research Background

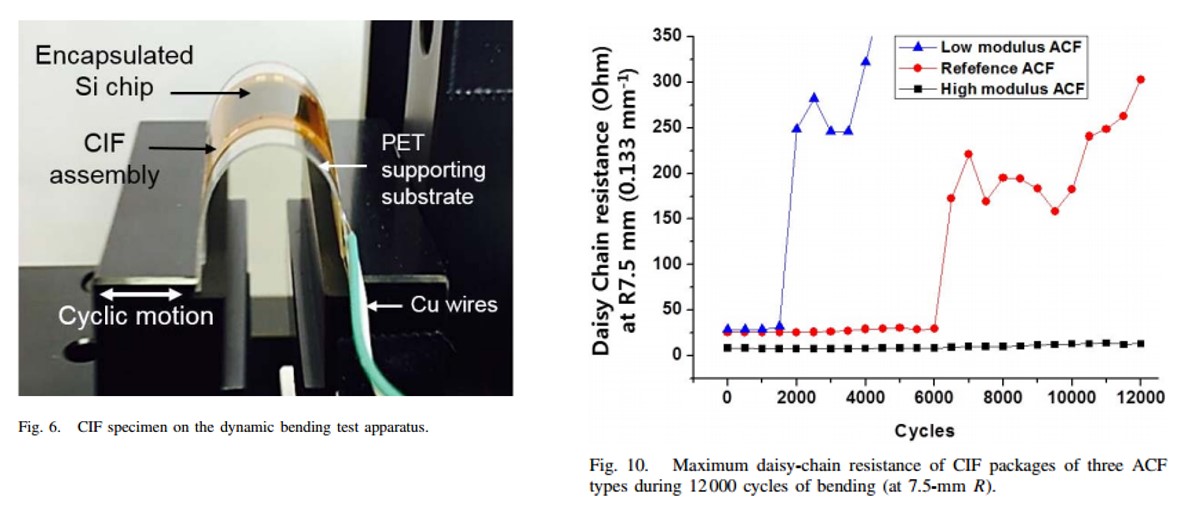

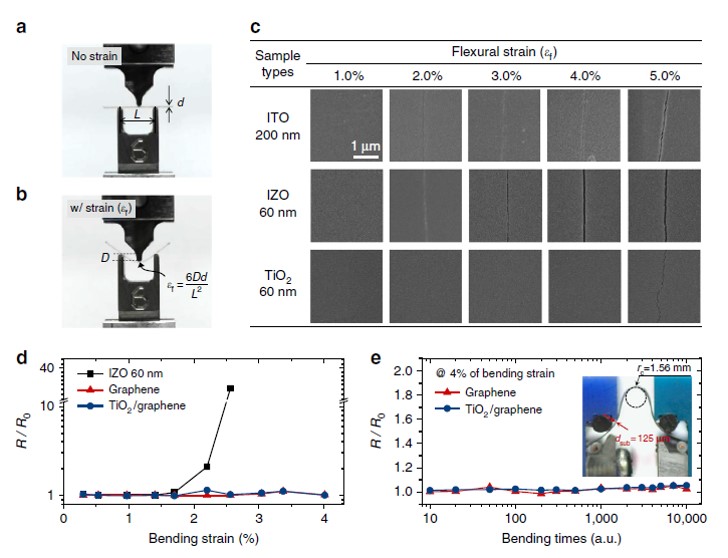

Flexible electronics are subjected to repetitive mechanical loading which results in mechanical failures such as fracture of electrodes, interfacial delamination and rupture of flexible substrates. Therefore, mechanical reliability of flexible electronics should be investigated under repetitive loading condition.

- Cyclic bending test of flexible electronic packaging

- Mechanical properties and electronic properties of electrodes for flexible OLEDs under flexural strain

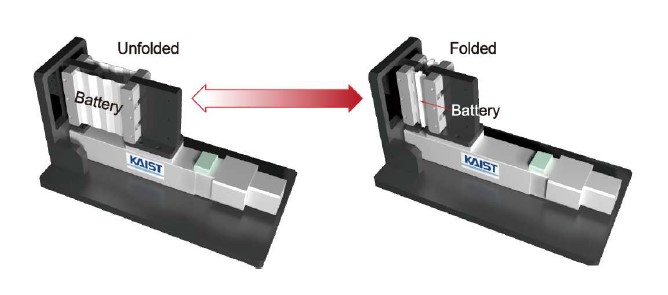

- Repetitive folding test of wearable textile battery