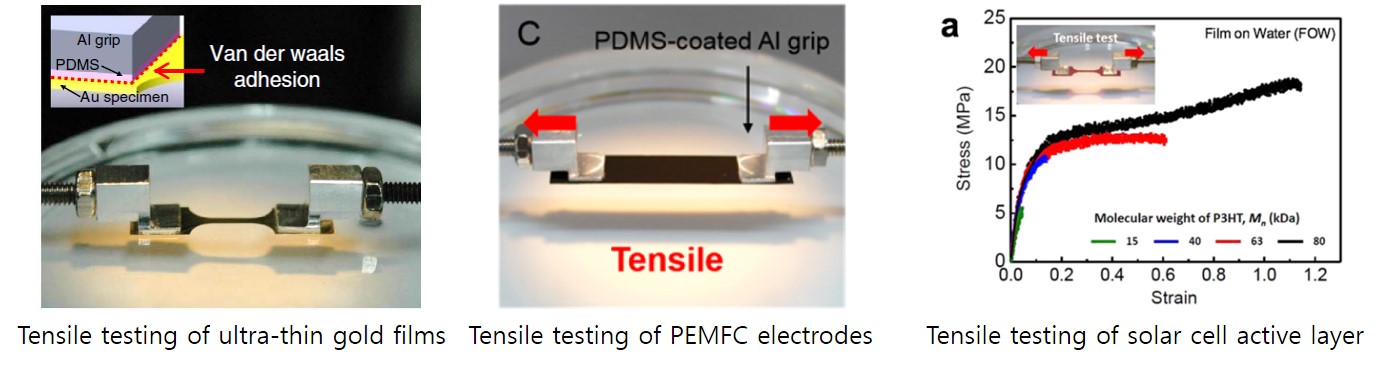

Tensile test

Research background

- Tensile testing on water surface

Mechanical properties of thin films are fundamental factors to evaluate and improve mechanical reliability of various devices. However, it is very challenging to conduct tensile test of thin films. Our lab has developed adequate tensile testing systems for diverse thin materials. Exact mechanical properties such as elastic modulus, tensile strength and elongation are measured by using several tensile testing methods.

Bending test

Research background

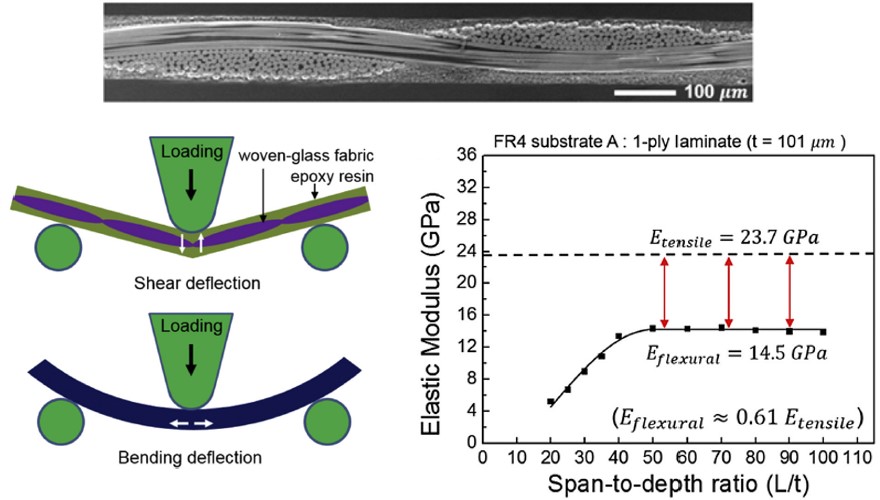

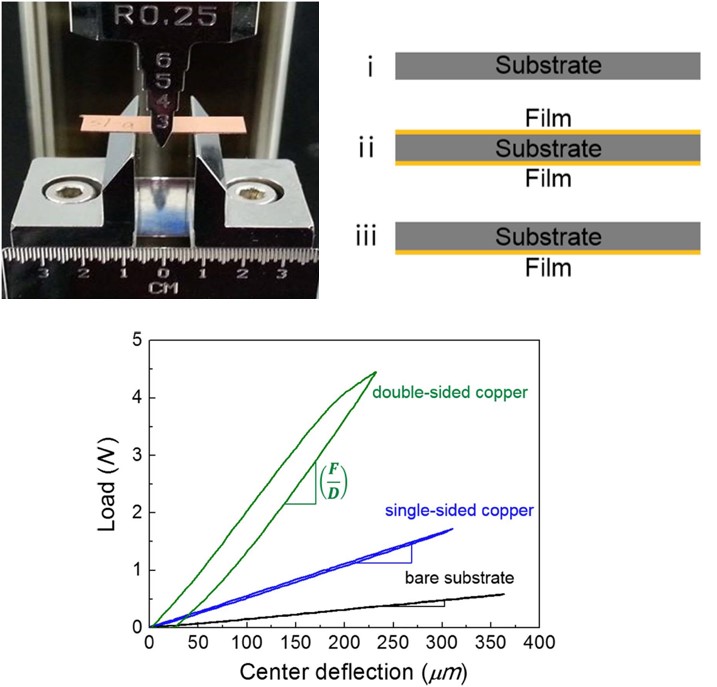

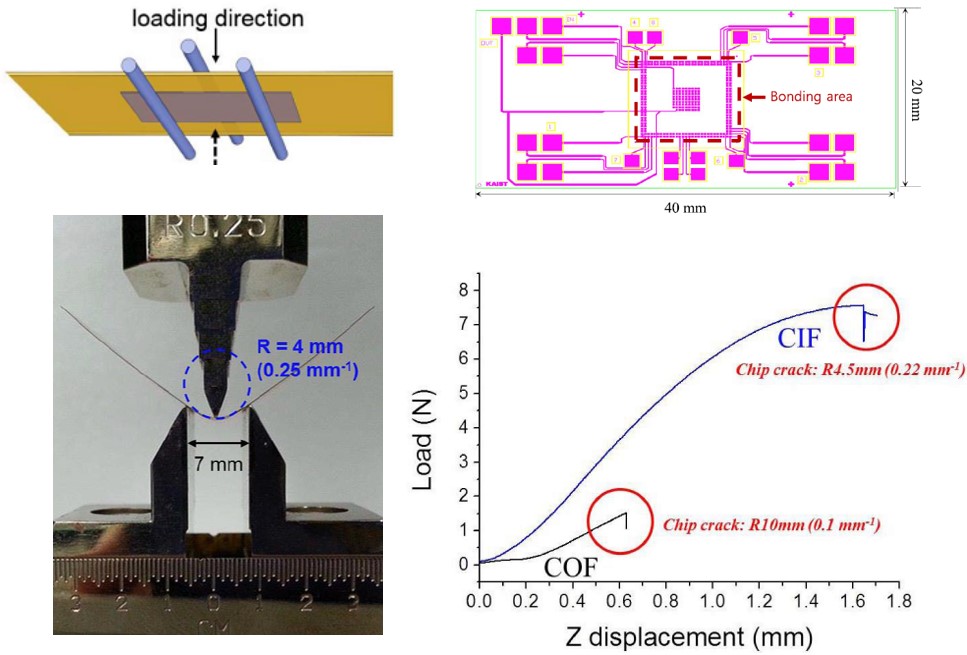

Bending properties of various materials in flexible devices are critical because they undergo frequent bending deformation in their applications. Three-point or four-point bending tests are utilized to measure the flexural properties including flexural modulus and flexural strength, which directly represent the mechanical response of the materials under the bending such as warpage.

- Flexural modulus of thin composite laminates (FR4 substrates)

- Modulus of thin films with film-on-substrate structure

- Chip-embedded flexible package

CTE

Research background

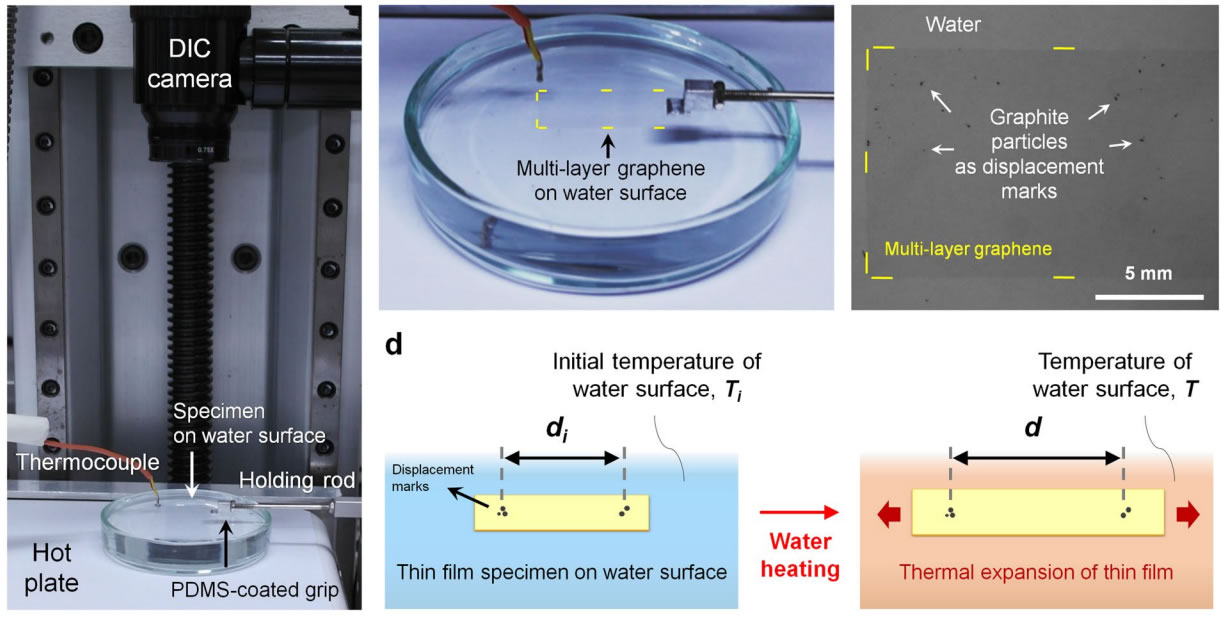

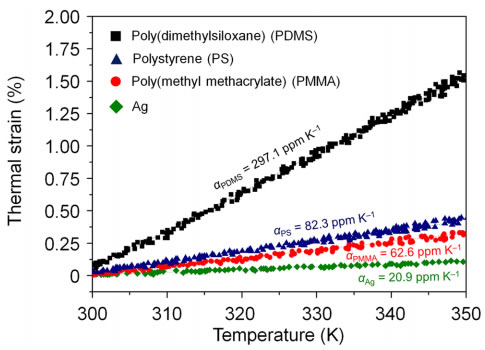

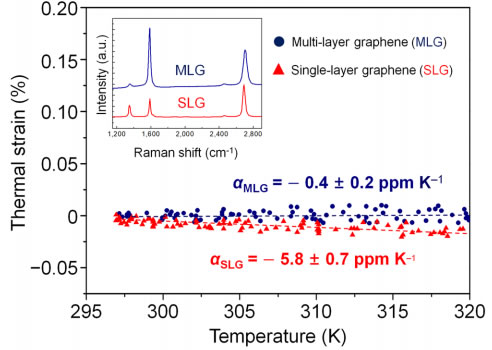

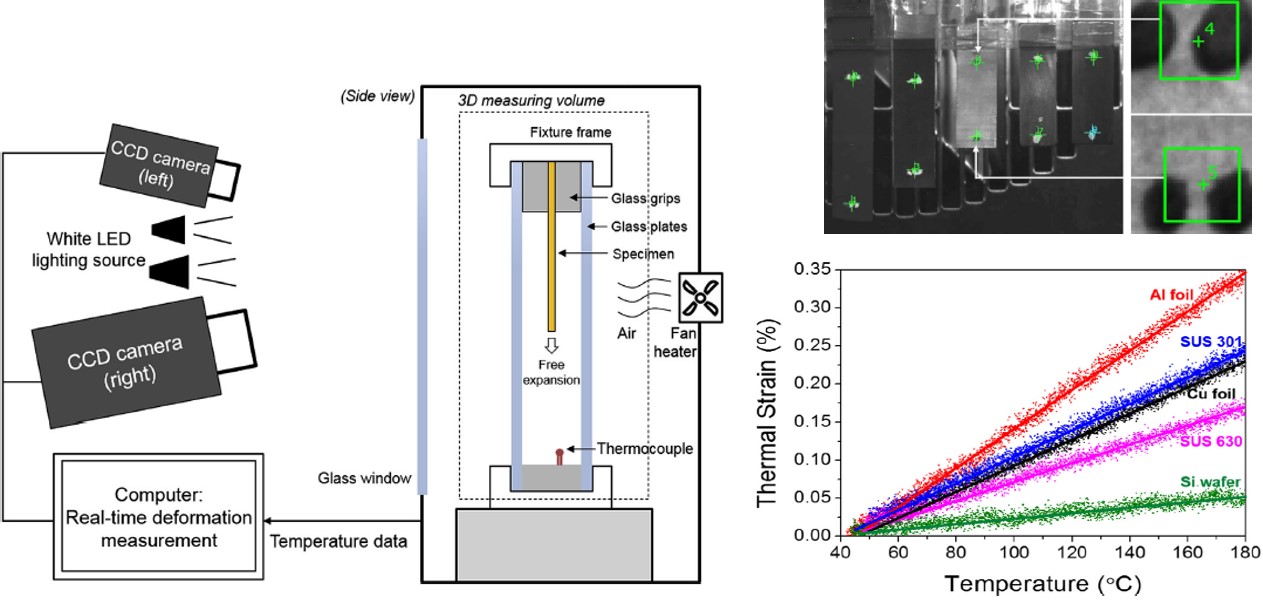

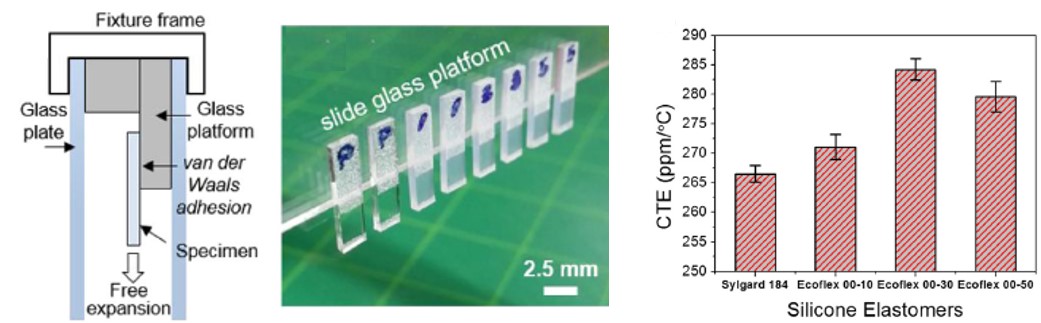

The coefficient of thermal expansion (CTE) is an important material property that indicates the dimensional stability of a material under temperature variations. The CTE should be accurately measured to predict thermal stress that develops in a electronic package during its thermal fabrication or the usage at high temperature. We utilize digital image correlation (DIC) method for precise strain measurement in a non-contact manner. This method is applied to most of the engineering materials ranging from low CTE ceramics to high CTE elastomers. The optical strain evaluation method also imparts high-throughput measurement.

- Non-contact, high-throughput CTE measurement

- CTE of very soft elastomers

- Thin film CTE measurement

Coefficient of thermal expansion (CTE) for thin flm has been measured only from change in thickness because thin film has to be constrained on a solid substrate. However, thin film CTE shows different values depending on the supporting solid substrate. Here, a novel measurement method is suggested to quantitatively measure the in-plane thermal expansion of thin flms foating on a water surface. In-plane thermal expansion of thin flms on water surface is achieved by heating the water. The CTE is measured through a digital image correlation (DIC) technique. The method can be applied to measure the CTE of polymer, metal, and graphene with a thickness ranging from a micrometer to one-atom-thickness. The CTE measurement method can provide understanding of the intrinsic thermal expansion behavior of thin flms including emerging two-dimensional materials.